Fuji Innovative Materials Research Laboratory (Overview of Technologies) Printing paper-related technologies

The structure of coated paper and its optimization

Coated paper is structured through coatings, primarily composed of pigments, that are applied to one or both surfaces of a base paper layer. In addition to the pulp in the base paper, differences in the of structure of the coating layers formed by pigments greatly impact the quality of coated paper in terms of brightness, gloss, smoothness, ink receptivity, and other factors. By optimizing the materials used in both the base paper layer and the coating layers, we aim to produce coated papers of higher quality.

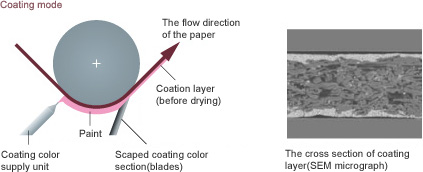

Leading-edge coated paper manufacturing technologies

In general coated paper, uniform layers of coating are formed on the surface of base paper by blowing pigment and adhesive-based coating onto the paper and then using a blade or similar tool to scrape away coating applied in excess. Glossy coated paper is obtained through the calendering process, as needed for the quality desired. The Research is working to establish utilization technology through the use of a pilot coater able to implement a variety of technologies, including the latest curtain coatertechnology.

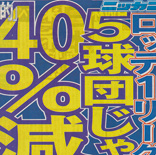

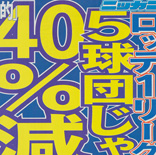

Newsprint that is both high quality and environmentally friendly

Keeping pace with the increase in newsprint color pages and faster printing speeds, we continue to enhance the functionality of newsprint through the development of original technologies. Achieving beautiful color printing calls for controlling print-through and preventing the creation of dust during printing. At our newsprint production mills, we manufacture our own highly- functional calcium carbonate filler suitable for newsprint, mix this with paper to control print-through and the prevent creation of dust during printing, and use surface finishing agents developed in-house that allow us to adapt to faster printing speeds. Our newsprint contains a high ratio of post-consumer content achieved from the use of waste paper recycling technologies. We will continue to advance technological development aimed at newsprint that offers both high quality and environmental friendliness.

Print-through on high quality news print

Conventional newsprint

High-quality newsprint

Development of highly-functional fillers and advanced utilization technology

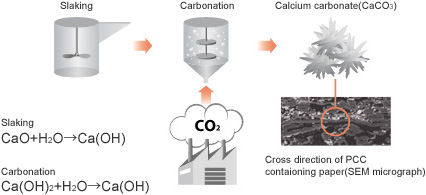

We produce calcium carbonate at many of our paper mills, using it as a filler (bulking agent) for paper. The calcium carbonate manufacturing process uses materials derived from limestone, which is available in abundance in Japan, and fixes CO

2

gas emitted at the mills. This is an environmentally friendly system which helps reduce greenhouse gas emissions.

The form of the calcium carbonate can be controlled by adjusting reaction conditions during the carbonation process. We control the form of calcium carbonate as needed for various paper applications, and further employ advanced utilization technologies developed in-house. By doing so, we have achieved higher quality paper matched to applications, such as paper with high brightness, opacity, and bulk, as well as acid neutralization for newsprint.

- Inquiries

-

- Inquiries via form