|

November 8, 1999

Nippon Paper developed a new ecological pulping process

Nippon Paper developed a new ecological pulping process

in cooperation with Kawasaki Kasei and Asahi Glass

Nippon Paper Industries Co., Ltd.

The newly developed Electrolytic, highly concentrated polysulfide (PS), cooking liquor system has three main benefits:

•Improved Pulp Yields

•Conservation of raw materials

•Feasibility of Total Effluent Free (TEF) bleaching process

System overview & history

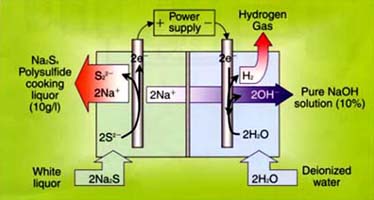

-White liquor (WL), the kraft pulping (KP) agent is electrically oxidized to produce PS liquor (with excellent current efficiency and pure sodium hydroxide {NaOH} simultaneously). The PS liquor is then added to the cooking digester.

-A specially designed bench scale cell was developed at the Nippon Paper Industries mill in Iwakuni, Japan in 1997.

In June of 1999, the Ministry of International Trade Industry funded the project research, in part, through a government subsidy for developing Creative Industrial technology.

A pilot- scale cell was installed at the Iwakuni plant to verify the long-term operational techniques. Results of this research were presented in Orlando, Florida, USA and in Morioka City, Japan during November of 1999.

Evaluation of a mill-scale trial is currently in progress.

Improved Pulp Yields

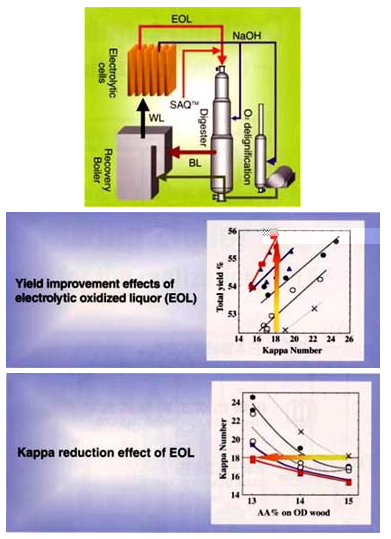

By adding the highly concentrated polysulfide (PS) cooking liquor produced by this electrolytic process to the digester, a great improvement of pulp yields can be obtained.In addition, a reduction of overall costs is realized.

|

Conservation of raw materials

Electrolytic system saves approximately 5 percent in raw materials, wood chips, compared with conventional KP cooking. For example, it is possible to conserve wood resources of 50,000 m3 per year at a pulp mill producing 1,000 tons of pulp per day in a year's time.

Feasibility of Total Effluent Free (TEF) bleaching process

Effluents of total chlorine free (TCF) bleaching, which has ozone bleaching and hydrogen peroxide bleaching, etc., can be concentrated and recovered into the recovery boiler. It can be used to generate energy and act as the cooking agent when TCF bleaching is utilized. It is environmentally efficient to pursue this TEF process; to combine TCF with the pure sodium hydroxide (NaOH) produced in this electrolytic system in the future.

In summary, to improve pulp yields, reduce overall costs, use fewer natural resources, and in developing revolutionary environmentally friendly pulping processes, Nippon Paper Industries Co Ltd., Kawasaki Kasei Chemicals Co Ltd. And Asahi Glass Co Ltd. has demonstrated that the future of research and development lies in cooperative efforts for industrial and ecological concerns. The Electrolytic Polysulfide (PS) cooking liquor system is both ecological and efficient.