SUPERCHLONⓇAcid-modified Chlorinated Polyolefin

Acid-modified chlorinated polyolefin has an excellent adhesion to polyolefin substrates. Due to the introduction of polar groups, it also shows high performance of adhesion to substrates such as PET, ABS, and nylon, and to topcoat paints based on acrylics, polyurethanes, epoxies, and alkyds as well.

General Characteristics

| Appearance | Clear - Pale yellow pellets |

|---|---|

| Dry film | Clear, transparent and flexible |

| Solubility | Generally soluble in aromatic hydrocarbons |

| Viscosity |

Depends on chlorine content and molecular weight |

Products

| Grade |

Chlorinated content | Viscosity (mPa·s, 25℃) | Viscosity Measurement Conditions | Feature | ||

|---|---|---|---|---|---|---|

|

Solid Content (%) | Solvent Composition | |||||

| 3228S | 28 | 10-70 | 30 | Tol/IPA=97/3 | Good compatibility with acrylic resins | |

| 822S | 24.5 | 20-80 | 20 | Basic grade | ||

| 892LS | 22 |

Tol/CH/IPA= |

Good adhesion | |||

| 930S | 21 | 20-100 |

Tol/CH/IPA= |

For low temperature baking | ||

| 3221S | 21 | 5-50 |

Tol/CH/IPA= |

Good compatibility with acrylic resins | ||

| 2319S | 19.5 | 20-100 |

Good adhesion |

|||

The above numbers are for reference only.

Tol: Toluene, CH: Cyclohexane, IPA: Isopropyl alcohol

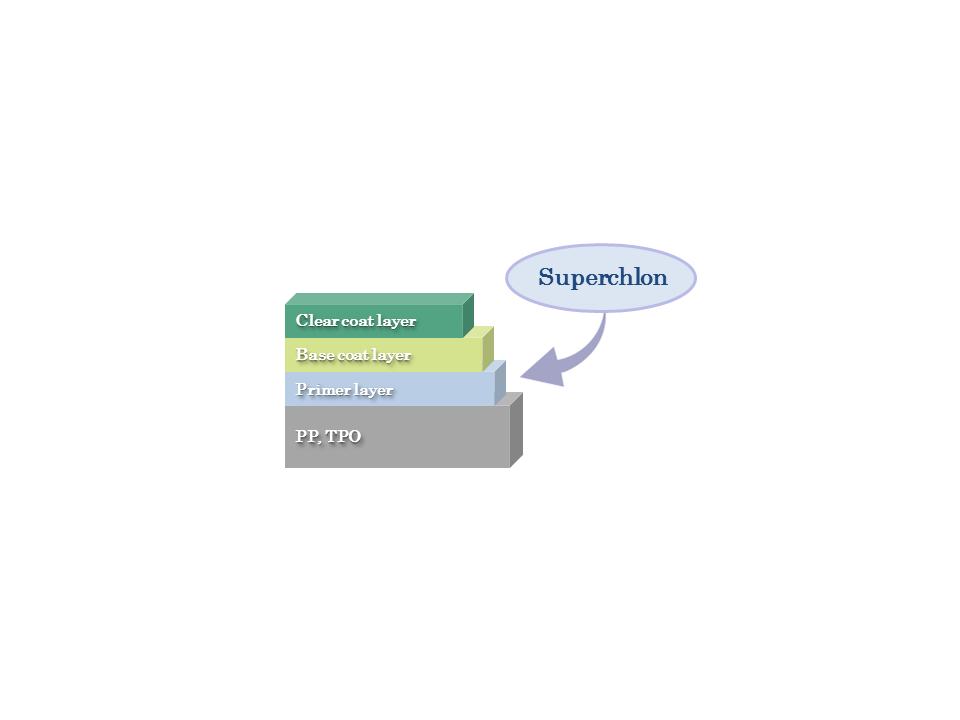

Usage

| Paint | Primer for polypropylene (PP) and/or thermoplastic olefin elastomer (TPO) (Bumper, wheel cap and other automotive parts) |

|---|---|

| Adhesive | Laminating adhesive for PP and/or TPO |

Example

Primer coating method for PP, TPO

Formulation example for primer

| Portion (weight) | |

|---|---|

| SUPERCHLON 822 (20% toluene solution) | 100.0 |

| TiO2 (Rutile-type) | 5.0 |

| Carbon black | 0.1 |

| Thixotropic agent (Polyamide-type) | 0.1~0.3 |

| Stabilizer (Epoxy resin) | 0.4 |

- Inquiry

-

- Telephone

-

Chemical Sales Dept.Ⅰ

+81-3-6665-5940