SUPERCHLONⓇSUPERCHLONⓇ

SUPERCHLONⓇis a chlorinated polyolefin which was introduced into the market in 1967 using NIPPON PAPER INDUSTRIES original production method. It shows high proformance of adhesion to polypropylene, thermoplastic olefin elastomer (TPO), and for low surface energy substrates containing olefinic material. It can be blended into primers, paints, inks, and adhesives to achieve excellent adhesion onto polyolefin-based substrates. Depending on the grade, it also adheres well to PET, ABS, nylon, and other substrates. With various softening points, chlorine content and molecular weight. SUPERCHLONⓇ can be selected depending on the use, purpose and conditions. Available in waterborne, solventborne and pellets (or solids).

| Type | Characteristics | Usage |

|---|---|---|

| Superior adhesion with PP and various plastics |

Binder, additive, |

|

| High compatibility with acrylic and/or urethane EVA paints due to the inclusion of a polar group in the resin | Primer, adhesive | |

|

Environmentally friendly waterborne emulsion providing similar properties to solvent-borne types |

Primer, adhesive |

Usage

|

Automotive parts |

Primer, paints, adhesives for automotive plastic parts |

|---|---|

| Film printing |

Ink binder, additive for film (gravure /silk-screen) printings |

| Packaging |

Adhesive for food wrapping film, plastic molded containers |

| Construction |

Primers, paints, adhesives for construction materials |

| Textile |

Adhesives for non-woven fabric, electrostatic flocking of plastic fiber |

|

Thermal transfer foil |

Adhesives for hot stamping foil |

| Synthetic paper | Plastic surface treating agent |

Characteristics

| Property | Chlorine content | Molecular weight |

|---|---|---|

| Solubility | Higher is better | Smaller is better |

| Compatibility with other resin |

Higher is better |

Smaller is better |

|

Weatherability |

Higher is better |

Bigger is better |

| Oil resistance | Lower is better |

Bigger is better |

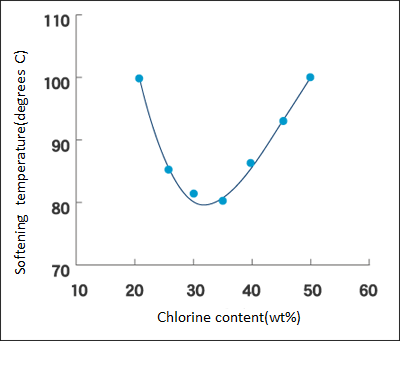

| Heat resistance | Lowest at 32 - 34 % |

Bigger is better |

| Drying properties | Higher is better |

Bigger is better |

|

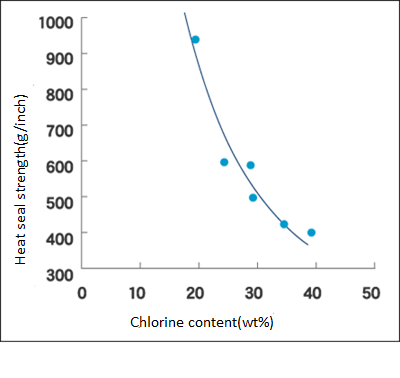

Heat-seal strength |

Lower is better |

Bigger is better |

|

Air-dry adhesion strength |

Preferably 30 - 34% | Smaller is better |

|

Pigment wettability |

Higher is better |

Smaller is better |

|

Gloss of the coating film |

Higher is better |

Smaller is better |

|

Tackiness of the coating film |

Higher is less-Tackiness |

Bigger is less-Tackiness |

Correlation between chlorine content and heat-seal strength

Film : PP 50μm

Sealing conditions: 110 degrees C, 1kg/cm2, 1 sec

Exfoliation conditions: 1.5cm width, 180 degrees, 50mm/min

Correlation between chlorine content and softening temperature

Packaging

- Liquid type (solventborne, waterborne)

-

15~16kg jerry can, 180~200kg drum

- Solid type (pellet)

- 15~20kg carton box

- Inquiry

-

- Telephone

-

Chemical Sales Dept.Ⅰ

+81-3-6665-5940